- Easy to Assemble

- Easy to maintain

- No Power, No electricity is used

- Less Manpower

- Install anywhere - no limitations

Conveyors

What are Gravity Roller Conveyors?

Excel Conveyors manufacturers of Gravity Roller Conveyors. Gravity Conveyors move the product by its weight. The Gravity Rollers are mounted between two frames. The two ends of the conveyors have different heights so that a slope is created between two ends. The product is placed on the rollers and carried to the other end of the conveyor. Gravity Conveyors do not need any electricity or any power to run.

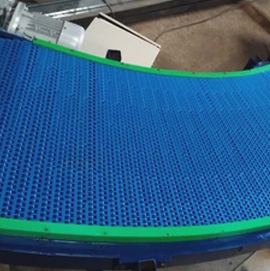

What are the types of Spiral Conveyors?

Spiral Conveyors are used to carry material along the spiral axis upwards or downwards. The

spiral media may be different such as rollers, modular belts modular slats, but the ultimate

aim is to convey material.

Spiral Conveyors are the Best Space Saving option. Again it

depends on the material/component dimension to be transferred. Spiral conveyors are also

used in bakery where in process cooling is required. In this case, the speeds are very slow.

What is its all about Pallet Conveyors?

Pallet Conveyors are simple roller conveyors but are designed to take heavy loads of pallets such as 2tons. Pallet conveying poses a challenge in conveying because of higher weights and higher heights.

Our projects

.jpg)

.jpg)

.jpg)

.jpg)

How do Gravity Roller Conveyors work?

Gravity Conveyors work like a slide in a children's play area. As the slide takes down the child from top to bottom by gravity, similarly gravity conveyor runs the product from the top end to the bottom ends.

-

What are the Features or Benefits of Gravity Roller Conveyors?

-

What are the limitations of Gravity Roller Conveyors?

Limitations of Gravity Roller Conveyors are as below.

- Very Low Weights do not slide because there is no gravitational force. The gravity roller conveyor in such cases requires a higher slope.

- Due to increased slope, longer-length gravity roller conveyors are not possible for low weights.

- Heavyweight items need extra care such as speed control rollers are to be used.

- Not suitable for higher or longer lengths.

- The controlled motion of products is not possible on gravity conveyors.

-

What are Applications of Gravity Roller Conveyors?

- Semi-Assembly line of any product in various industries.

- Pallet conveying for jumbo bags or boxes or bags etc.

- Warehouse Conveyors

- Godown Conveyors

- Factory Conveyors

- Unloading from vehicles

- Carton Box Conveying

- Plastic Crates/totes conveying

- Storage Racks for FIFO / LIFO

- Live Storage Racks

-

Where are Spiral Conveyors used?

Spiral Conveyors are used in various industries for vertical transfer of materials and articles.

- Warehouse & storage

- e-commerce

- Food & Bakery

- Pharma

- FMCG

- many more

-

What are Design Options in Spiral Conveyors?

Options are dependent on -

- Number of floors

- Number of Inputs

- Number of outputs

- Purpose

- Direction - Upward / downward / both

-

What are components of a typical Pallet Conveying Line?

Depending on the layout a pallet conveying line may need below units

- Pallet Motorised Conveyor

- Pallet Gravity Conveyor

- Pallet Turntables

- Pallet Cross Transfer Units

- Pallet Drag Chain Conveyors

- Pallet Lift & Rotate

- Pallet Transfer Unit

- Pallet Pairing Unit

- Pallet Dispensing Unit

-

What are Pallet Conveyors?

Pallet Conveyors are again of two types Pallet Gravity Conveyors and Pallet Powered Conveyors. Pallet gravity roller conveyors need more precaution during design than powered conveyors. The weight of the pallet and height both play a vital role while the design of the pallet conveyors. The rollers, as well as structure, should be able to handle the weight of the pallets. Read - How to calculate load carrying capacity? Also Read What is the load-carrying capacity of rollers?

The pallet gravity roller conveyors should also have speed control rollers along with proper pallet stopping arrangements and safety features. Due to weight, the pallet speed increases on gravity roller conveyors. It is necessary to reduce the speed of the pallet before it reaches the unloading end. Speed control rollers reduce the speed of the pallets so that the pallet stops at the unloading end safely.

The Powered Roller Conveyors uses pallet conveyors with rollers of diameter 76mm x 3mm thick with sprocket such as 5/8"x15Teeth. Powered Roller Conveyors may have sped up to 20meters/min.

Excel Conveyors manufactures pallet conveyors which are Rigid, robust, and with adequate safety measures.

-

What are Pallet Turntables, Cross Transfer Units, Lift & Rotate ?

Pallet Turntables, Cross Transfer Units, Lift & Rotate are more or less and do the same function. They have one thing in common. They work with the orientation of the pallet. Pallets have stringers that support the top platform to take loads. There are various types of pallets in terms of size and materials.

While the pallet is moving on roller conveyors, the bottom stringers are at a right angle to rollers. The right angle position of the stringers needs to be maintained at cross transfers. All the above units do change the orientation.The Turntables receive the pallet on it, and after that, it turns 90Degree Or 180Degree.

The Cross Transfer Units receive the pallet via a drag chain conveyor which has more height than rollers. It lowers down on rollers and rollers move the pallet on the line.

Lift & Rotate - is a combination of turntable & cross transfer units.